Management system guidance

8.0 Operation

ISO Navigator Pro™ is a free tool that provides practical, expert guidance for businesses wishing to interpret and better implement the requirements of ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018.

Our range of templates cover the requirements of ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018, and offer an easy way to implement your next management system.

8.1.3 Management of change

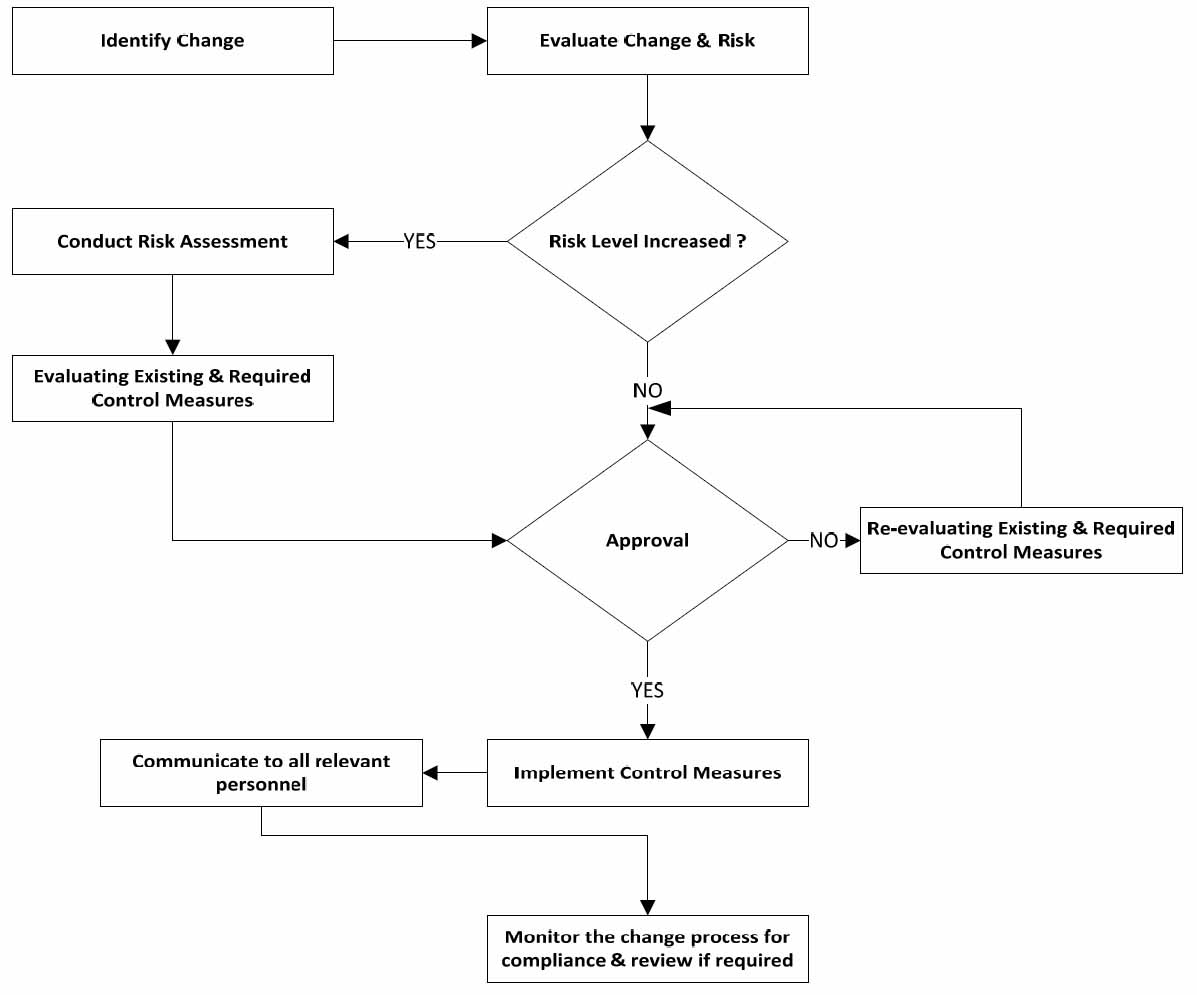

Change brings risk, whereas managing change reduces the risk. When changes to the operation are planned, is the effect on the OHS management system considered? Documented information needs to be retained relating to planned changes and their potential impact on the OHS management system.

Whether it is the introduction of a new equipment, a new maintenance procedure, or a move to new premises, your OHSMS needs to cover the identification of any changes that may pose a risk to safety. These include the changes that would have a noticeable impact on your resources, materials, procedures, processes, training, management control, and above all your people.

Risk assessment is a key part of the process, so when you decide to make a change, start by assessing the overall risk of the change itself. You should include a risk assessment of each issue, so that you can take any necessary steps to minimize the risks and their potential effects.

Safety management requires that organizations manage the safety risks associated with organizational and operational changes. Staff concerns about workload, job security and access to training are associated with significant change in organizations and can have a negative impact on safety culture. The degree to which staff feel involved in the development of change and understand their role in the process will also influence the safety culture.

The greatest resource of any organization are its people, so strategies for managing both real and perceived change, or concerns and attitudes, should be addressed during transition planning. It is likely that during the first few months, Top management will need to regularly reinforce the benefits of the transition project to ensure that your employees maintain focus and motivation for upgrading the OHSMS.

Adjusting the OHSMS documents should also be expected as staff become accustomed to the requirements and begin to suggest improvements in usability. Instant business improvements may be initially observed; however, experience suggests that there is a lag phase before consistent improvements become the norm.

The benefits to the organization of a properly functioning OHSMS are not just restricted to the knowledge that it complies with regulatory requirements, but that it has the discipline to manage customer requirements effectively.

The organizational migration from a pre-certification state to one that operates within the rigors of an ISO based management system is not a casual task. There must be a tightening of how processes are managed and there are often changes in staff interactions, responsibilities and accountability. Such changes are unlikely to succeed without the dedicated support of both the executive and operational management.

The greatest resource of any company are its people, so strategies for managing both real and perceived change, or concerns and attitudes, should be addressed during the initial planning of the OHSMS. It is likely that during the first few months, Top management will need to positively reinforce its requirements on a routine basis to ensure that staff maintain motivation and do not lapse back into old habits.

Iterative adjustment of new or existing management system documentation should also be expected as staff become accustomed to the requirements and begin to suggest improvements in usability. Instant business or operational improvements may initially be observed. The benefits of a properly functioning OHSMS are not just restricted to the knowledge that it complies with regulatory requirements but that it has the discipline to manage customer requirements effectively and to mitigate risk.

More information on PDCA

Planning

Context

Planning

Support

Doing

Support

Operations

Checking

Monitoring, measurement, analysis and evaluation

Acting

Improvement

Want to know more?

- Read our customer's feedback

- Client list - who's using our templates?

- How the templates are formatted and download examples

- Why we use turtle diagrams and process maps

- What's the difference between a process and a procedure?

- About documented information

SSL certification

A certificate guarantees the information your internet browser is receiving now originates from the expected domain - https://www.iso9001help.co.uk. It guarantees that when you make a purchase, sensitive data is encrypted and sent to the right place, and not to a malicious third-party.

Free PDCA guidance

ISO Navigator™ is our FREE online training tool that shows you how to apply the principles of PDCA to your operations. We also offer many helpful templates that get you on the road to documenting your management system, please visit the download page.